Your daily selection of the hottest trending tech news!

According to Digital Trends

A paper describing the work has been accepted to the ACM CHI Conference on Human Factors in Computing Systems, which takes place in April in Montreal.

Do you remember the color-changing dress that proved especially divisive when it made the rounds a couple years back. Was it black and blue or white and gold? The Massachusetts Institute of Technology’s Computer Science and Artificial Intelligence Laboratory (CSAIL) is looking to stir up a similar controversy — although this time it may be possible for the dress in question to be both black and blue and white and gold.

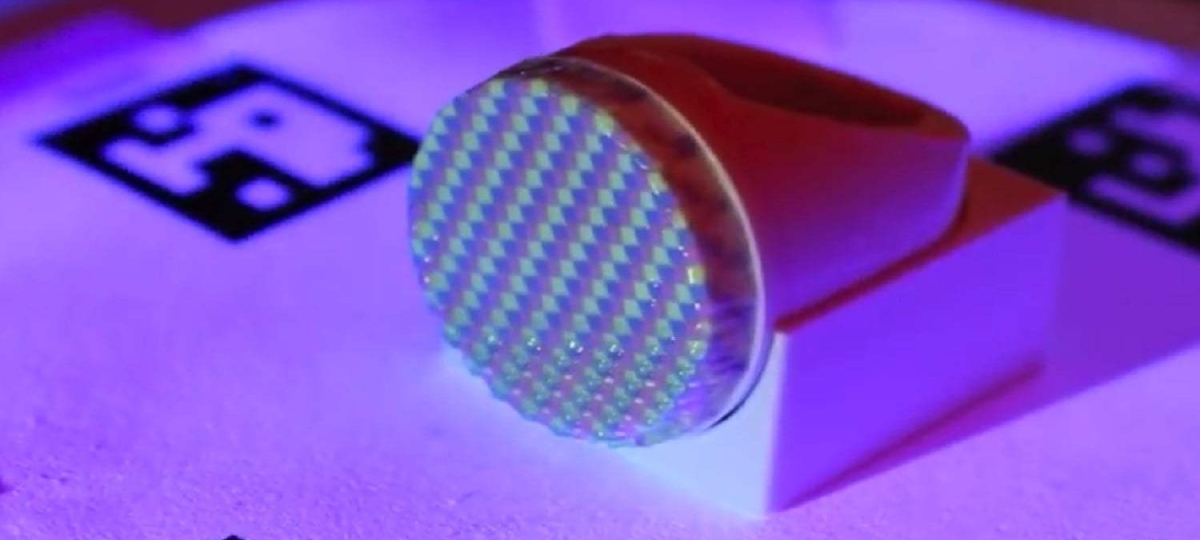

No, we’re not talking about any kind of “Schrödinger’s cat” thought experiment, but rather a new system called ColorFab that allows 3D printed objects to change color, courtesy of special dyes that can be activated and deactivated when exposed to different wavelengths of light.

“ With the amount of buying, consuming, and wasting that exists, we wanted to figure out a way to update materials in a more efficient way, which was largely the motivation behind this project,” MIT professor Stefanie Mueller, who led the project, told Digital Trends. “We’ve developed a system for repeatedly changing the colors of 3D-printed objects after fabrication in just over 20 minutes. Specifically, we can recolor multicolored objects using a projector model and our own 3D printable ink that changes color when exposed to UV and visible light.”

MIT CSAILAccording to Mueller, the technology could allow users to change the color of different items of clothing in order to accessorize them, or for a retail store to be able to customize its products in real time if a buyer wants to see an item in a different color. It currently takes 23 minutes to change an object’s color, but they hope it will be possible to speed up the process as the project advances. The hope is that it could one day be used like the color-changing nails in the movie Total Recall, in which a receptionist is able to change the color simply by touching her nails with her pen.

“This is just a research prototype at this point, so there are no immediate plans to commercialize,” Mueller said. “As a next step, we hope to speed up the printing process by using a more powerful light and potentially adding more light-adaptable dye to the ink. We also hope to improve the granularity of the colors so that more nuanced patterns can be printed.

- Got any news, tips or want to contact us directly? Email esistme@gmail.com

__

This article and images were originally posted on [Digital Trends] January 29, 2018 at 02:27PM. Credit to Author and Digital Trends | ESIST.T>G>S Recommended Articles Of The Day